Die-cast metal models represent a more stable and defensible tangible asset class due to their superior material integrity and verifiable scarcity.

- Material science, not just aesthetics, dictates long-term value preservation by mitigating risks like zinc pest and physical degradation.

- Value appreciation is driven less by broad popularity and more by specific, verifiable factors like defunct airline liveries and limited production runs.

Recommendation: Treat your collection as a managed portfolio, focusing on proactive preservation and strategic acquisition of models with identifiable value drivers.

For the dedicated collector, the debate between die-cast metal and plastic models has often been a matter of personal preference—the satisfying heft of metal versus the crisp detail of plastic. However, from a wealth management perspective focused on tangible assets, this is not a question of taste but of performance and durability. Viewing these models as part of an investment portfolio fundamentally changes the criteria for evaluation. It shifts the focus from simple nostalgia to long-term value preservation, risk mitigation, and predictable appreciation.

While many collectors focus on rarity or brand, they often overlook the most critical factor that underpins an asset’s longevity: its material integrity. The conventional wisdom to “keep it in the box” is a passive strategy that ignores inherent material risks. The true key to a successful collection portfolio isn’t just acquiring rare items; it’s understanding the material science that ensures they will survive to appreciate in value. An asset that degrades on the shelf is not an asset at all; it’s a liability.

This analysis will reframe the discussion through the lens of a portfolio manager. We will move beyond the surface-level debate and delve into the specific material vulnerabilities, preservation strategies, and value drivers that distinguish die-cast metal as a potentially more resilient long-term investment. By understanding how to manage the physical risks—from metallurgical decay to environmental damage—you can build a collection that not only brings you joy but also holds its value as a durable tangible asset.

This guide provides a structured approach to evaluating and protecting your collection. We will explore the critical factors that determine the stability and growth potential of die-cast aircraft models as a serious component of your investment strategy.

Summary: A Financial Advisor’s Guide to Die-Cast Aircraft Investment

- Why zinc pest destroys collections and how to spot early signs?

- How to remove dust from die-cast models without scratching the paint?

- Die-cast vs Plastic: which material captures fine panel lines better?

- The weight danger: are glass shelves strong enough for a heavy metal aircraft models?

- How to tighten loose stands on heavy metal aircraft models?

- Military vs Civil Aircraft Models: Which Collection Retains Value Better?

- How to Choose an Acrylic Case That Protects Your Models from UV Yellowing?

- How to Pair Correct Ground Support Equipment with Specific Aircraft Eras?

Why Zinc Pest Destroys Collections and How to Spot Early Signs?

From an asset preservation standpoint, zinc pest is the single greatest inherent risk to a die-cast collection. This irreversible intercrystalline corrosion process causes the zamak alloy—a mix of zinc, aluminum, magnesium, and copper—to swell, crack, and eventually disintegrate. While modern manufacturing has largely mitigated this by using 99.99% pure zinc in modern zamak alloys, models produced before the 1980s, and even some from less reputable modern brands, remain vulnerable. Ignoring this threat is akin to holding a bond without understanding its credit risk.

As a Hearns Hobbies Expert notes in their Zinc Pest Prevention Guide:

Temperature stability is crucial. Zinc pest accelerates with temperature fluctuations, so keeping your collection in a climate-controlled environment helps. We’re talking consistent temps around 20-22°C if possible. Avoid storing models in garages, sheds, or anywhere that gets hot in summer.

– Hearns Hobbies Expert, Zinc Pest Prevention Guide

Early detection is paramount for isolating affected models and preventing a “contagion” of despair in your portfolio. You must become adept at spotting the initial, subtle signs of material failure before they lead to a total loss of value. The image below highlights the tell-tale textures of this degradation.

The primary indicators are not always dramatic cracks. Look for fine, hairline fractures on the surface, a rough “orange-peel” texture, or small blisters under the paint. These are the first signs that the alloy is beginning to expand internally. Proactive inspection is the most effective tool in your risk management arsenal.

Early Detection: The “Sagging Door” Indicator

For models with moving parts like cabin doors or landing gear, their alignment serves as a canary in the coal mine. As zinc pest causes the fuselage to expand, the tiny, high-stress hinge points are often the first to fail. A door that no longer sits flush with the body or a landing gear strut that appears misaligned is a critical red flag. These subtle geometric distortions indicate that the underlying metal is swelling, and the model’s structural integrity is compromised.

How to Remove Dust from Die-Cast Models Without Scratching the Paint?

While less dramatic than zinc pest, improper cleaning is a leading cause of preventable depreciation in a model collection. Every scratch, swirl mark, or faded decal chips away at the asset’s pristine condition, which is a key driver of its secondary market value. The goal of dusting is not merely cleanliness, but value preservation. Using household dusters or abrasive cloths can inflict micro-scratches that dull the factory finish and reduce the model’s investment-grade quality over time.

A professional, tiered approach is necessary, treating your models with the same care a conservator would afford a museum piece. This means using tools and materials designed specifically for delicate surfaces. The wrong technique can cause more damage than years of neglect. Your cleaning protocol should be as methodical as your acquisition strategy, ensuring you protect the paint and intricate details like antennas and pitot tubes, which are easily broken.

Museum curators recommend a multi-level cleaning system that adapts to the level of dust and dirt, minimizing physical contact whenever possible:

- Tier 1 – Routine Dusting: For light, regular maintenance, use high-quality, soft natural bristle makeup brushes. Their fine bristles can access tight spaces around landing gear and engine pylons without pressure. A specialized, low-pressure air blower designed for camera lenses or models is also ideal for contactless dust removal.

- Tier 2 – Deep Cleaning: For models with accumulated grime, never use water or household detergents. Instead, opt for precision cleaning gels or non-abrasive polymer solutions formulated for collectibles. These products lift dirt without requiring rubbing.

- Tier 3 – Restoration: Specialized model waxes should be considered a last resort, used only for restoring a dulled finish after a thorough assessment. Incorrect application can alter the original sheen and damage delicate decals.

Ultimately, the best cleaning strategy is preventative. As collectors know, keeping models in a cool, dry, and enclosed environment significantly reduces the need for aggressive cleaning, thereby preserving their condition and value.

Die-cast vs Plastic: Which Material Captures Fine Panel Lines Better?

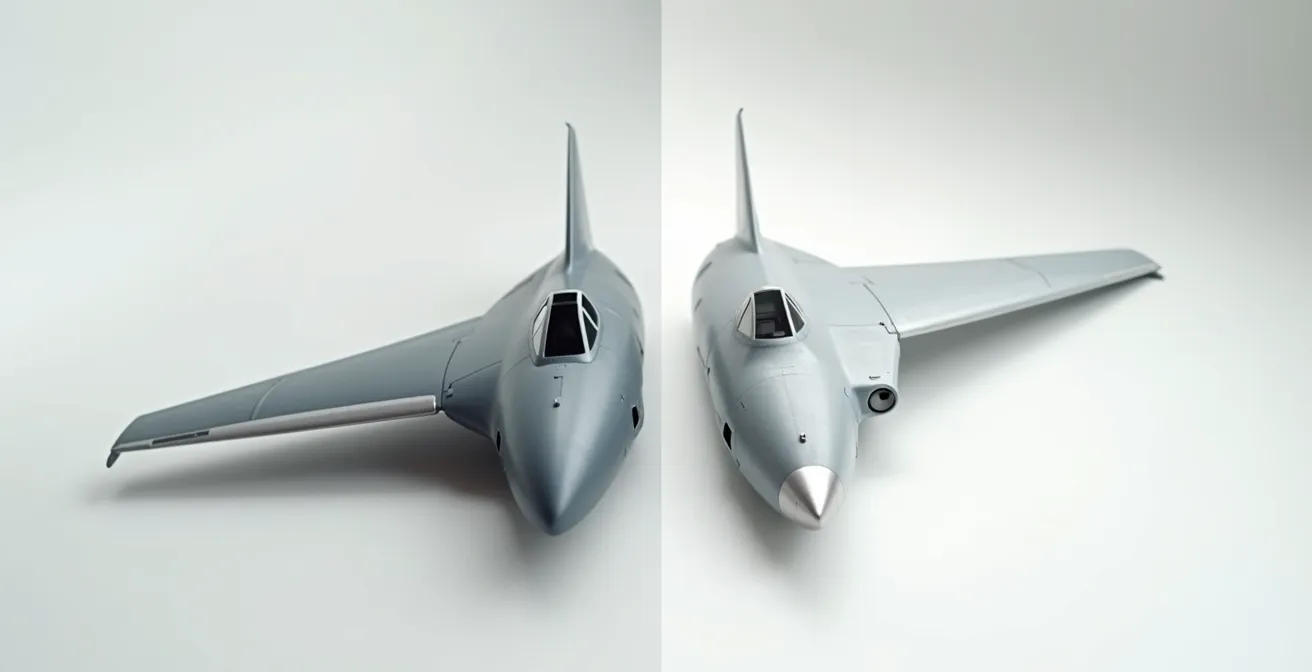

In the investment evaluation of die-cast versus plastic, the rendering of fine detail is a crucial differentiator. Panel lines—the subtle grooves on an aircraft’s skin—are a hallmark of a high-quality model. Here, the materials present a distinct trade-off. Injection-molded plastic, being a less viscous material during production, can fill molds with extreme precision. This results in exceptionally sharp and narrow panel lines, a feature highly prized by kit-builders and connoisseurs of fine detail.

Die-cast metal, by contrast, is a hotter and thicker material during the casting process. Consequently, the resulting panel lines are often softer, wider, and less defined than their plastic counterparts. While modern die-casting has improved significantly, a fundamental material difference remains. For a collector focused purely on the crispness of surface detail, a high-end plastic kit often has the edge. The side-by-side comparison below illustrates this difference in texture and definition.

However, from a portfolio perspective, this is not a simple win for plastic. Die-cast’s value proposition lies in its durability, weight, and the “finished product” nature that appeals to a different segment of the market. The target collector for pre-assembled die-cast models prioritizes the tangible feel and robust presence of metal over the microscopic fidelity of panel lines. Furthermore, the most sought-after die-cast models are often in scales where this difference is less pronounced. An analysis shows that for many collectors, 1:200 and 1:400 scales represent 65% of collector preferences, sizes where the heft of die-cast metal provides a satisfying sense of substance and value.

The choice is a strategic one: are you investing in the microscopic perfection favored by hobbyists, or the durable, tangible presence favored by collectors of finished assets? For long-term hold and display, the resilience of die-cast often outweighs the finer panel lines of a delicate plastic model.

The Weight Danger: Are Glass Shelves Strong Enough for a Heavy Metal Aircraft Models?

The significant weight of die-cast models is a double-edged sword. While it provides a satisfying sense of quality and substance—a key part of its appeal as a tangible asset—it also introduces a serious storage risk that is often underestimated. A single display shelf failure can wipe out thousands of dollars in assets in an instant. Standard decorative glass shelves, especially those made of annealed (non-safety) glass, are simply not designed to handle the concentrated load of a die-cast collection. For instance, a single 1:200 scale wide-body die-cast model can weigh up to 2.5 kg. A row of five such models exerts 12.5 kg of pressure, often exceeding the safe load limit of an unbraced glass shelf.

From a risk management perspective, your display infrastructure must be considered as critical as the models themselves. Choosing inadequate shelving is an unforced error that can lead to catastrophic loss. Tempered glass, which is four to five times stronger than annealed glass and shatters into small, blunt pieces rather than sharp shards, is the absolute minimum requirement. However, even with tempered glass, thickness and span between supports are critical variables that must be respected.

Before entrusting your collection to any glass surface, a thorough safety audit is not just recommended—it is mandatory. You must assess the material, its dimensions, and the total weight it is expected to bear. Failing to do so is an unacceptable risk to your portfolio.

Checklist for Glass Shelf Safety Assessment

- Identify Glass Type: Carefully inspect the corners of the shelf for a small, etched stamp indicating it is “Tempered” or “Safety Glass.” If no marking is present, assume it is weaker annealed glass and not suitable for heavy collections.

- Measure Thickness: Use a caliper to measure the glass thickness. An 8mm thickness is the minimum for a standard die-cast collection, with 10mm or 12mm being strongly recommended for larger scale models.

- Check Span Between Supports: Measure the distance between the shelf brackets. For 8mm tempered glass, the span should not exceed 60cm to support a distributed load of approximately 10-15kg. Reduce this span for heavier loads.

- Calculate Total Load: Do not guess. Count the number of models on the shelf and multiply by their average weight. Always calculate for the maximum potential load, not the current one.

- Distribute Weight Strategically: Position the heaviest models (e.g., 1:200 scale multi-engine bombers or airliners) directly over the shelf supports, with lighter models placed in the center of the span.

For extensive or particularly heavy collections, it is prudent to move beyond glass altogether and consider solid wood or professionally installed reinforced wall-mounted systems. Your display should be an investment in security, not a point of failure.

How to Tighten Loose Stands on Heavy Metal Aircraft Models?

A common but often overlooked issue in maintaining a die-cast collection is the gradual loosening of display stands. The constant pressure exerted by a heavy metal model on its stand’s mounting peg can, over time, cause the connection to become wobbly or unstable. This is more than a cosmetic annoyance; it’s a stability risk. A loose stand can lead to a model tilting, falling, and sustaining damage, directly impacting its value. Addressing this issue requires a delicate touch to ensure a secure fit without causing irreversible damage to the model itself.

The cardinal rule is to avoid permanent adhesives. Using super glue or epoxy may seem like a quick fix, but it permanently bonds the stand to the model, which can be a major red flag for future collectors and significantly decrease resale value. Professional restoration and repair always favor reversible solutions. The goal is to increase the friction and fill the small gap that has developed, not to weld the two pieces together. This maintains the model’s originality and integrity as a collectible asset.

Several non-destructive techniques can be employed. A common method is to apply a very thin layer of clear nail polish or a product like Pledge Floor Gloss to the stand’s peg. Once dry, this adds a micro-layer of material, effectively increasing the peg’s diameter for a tighter, more secure fit. Another reversible option is to wrap a small amount of plumber’s Teflon tape around the peg. This soft, malleable tape fills the gap and provides excellent friction without any chemical bonding. For any method, the key is to apply the material to the stand’s peg, never directly into the mounting hole on the model’s fuselage.

Preventative care is also crucial. When moving a model, always lift it by supporting both the aircraft and the base of the stand simultaneously. Never pick it up by the aircraft alone, as this puts immense stress on the mounting point. Ensuring the stand is appropriately rated for the model’s weight from the outset can also prevent the joint from loosening over time.

Military vs Civil Aircraft Models: Which Collection Retains Value Better?

When structuring a collection portfolio, the choice between military and civil aircraft models is a strategic decision akin to choosing between blue-chip stocks and high-growth tech stocks. Both have the potential for significant value appreciation, but they are driven by different market dynamics and carry different risk profiles. As noted in market analysis, some models appreciate in value and become collectibles, with certain releases soaring in resale price, but the drivers for this appreciation differ by category.

Military models generally appeal to a broader collector base. Their value is often tied to historical significance—famous conflicts, celebrated ace pilots, or iconic squadrons. This creates a large and relatively stable market. A model of a P-51 Mustang or a Spitfire has a perennial appeal rooted in well-known history. Civil aircraft, on the other hand, cater to a more niche but often more passionate audience. Their value is driven by different forms of scarcity and nostalgia, such as the liveries of defunct airlines (e.g., Pan Am, TWA), special commemorative designs, or milestone aircraft that marked a new era in travel (e.g., the first 747 or Concorde).

The following table breaks down the key investment characteristics of each category, providing a framework for portfolio allocation based on your risk tolerance and investment goals.

| Factor | Military Models | Civil Models |

|---|---|---|

| Market Size | Broader collector base | Niche but passionate |

| Value Drivers | Famous conflicts, ace pilots, iconic squadrons | Defunct airlines, milestone aircraft, retro liveries |

| Typical Premium | 20-50% over retail after 5 years | Up to 200% for rare airline liveries |

| Volatility | More stable due to larger market | Higher volatility, bigger gains/losses |

| Entry Cost | $50-150 average | $75-200 average |

As outlined by Flying Magazine, collectors often specialize, which concentrates demand. Some focus on specific aircraft types, while others pursue models from a distinct time period, airline, or livery theme. For the investor, this specialization is where opportunity lies. The highest returns in the civil category often come from predicting which “retro” liveries will become sought-after. For military models, a premium is often attached to limited releases depicting the aircraft of a specific, highly decorated pilot. A diversified portfolio may benefit from including both: stable, historically significant military pieces as a foundation, and rarer, high-growth potential civil models as a speculative component.

How to Choose an Acrylic Case That Protects Your Models from UV Yellowing?

Displaying your collection is part of the joy of ownership, but unprotected exposure is a direct threat to your investment. Ultraviolet (UV) radiation from sunlight or even indoor lighting is a silent destroyer, causing paints to fade, decals to yellow and crack, and plastics to become brittle. According to secondary market data, UV-damaged models lose 40-60% of their resale value. An acrylic display case is not a luxury; it is an essential piece of asset protection equipment. However, not all cases are created equal.

Standard, inexpensive acrylic offers little to no UV protection. To safeguard your portfolio, you must invest in museum-grade cases specifically engineered for conservation. This means looking beyond the price tag and scrutinizing the technical specifications of the acrylic used. The difference between a “dust cover” and a true “conservation case” lies in its ability to filter out the damaging portion of the light spectrum.

The image below shows a collector taking the proper care, understanding that the quality of the case is as important as the model within it. This level of meticulousness is what separates a casual hobbyist from a serious investor.

When selecting a case, your checklist should prioritize protective features over purely aesthetic ones. A truly protective case will be an investment in itself, but one that pays dividends by preventing irreversible depreciation.

- Verify UV Protection Rating: Do not settle for vague claims like “UV-resistant.” Look for a specific rating, ideally 99% UV filtering or higher. This specification should be clearly stated by the manufacturer.

- Check Acrylic Thickness: A minimum thickness of 3mm is acceptable for small models, but 5mm is recommended for larger displays. Thicker acrylic not only provides better structural integrity but also superior optical clarity, reducing distortion.

- Inspect Seam Construction: Chemically bonded or glued seams are far superior to tab-and-slot assemblies. Bonded seams create an airtight seal that is significantly more effective at preventing dust intrusion.

- Consider Museum-Grade Certification: For high-value pieces, seek out cases that meet established museum conservation standards, such as those used by institutions like the Smithsonian. These products are designed for maximum long-term preservation.

Key Takeaways

- Material Integrity is Paramount: The long-term value of a die-cast model is fundamentally tied to its material stability. Mitigating risks like zinc pest and UV damage is not optional; it’s a core asset management function.

- Protection is an Investment, Not a Cost: Investing in museum-grade display cases, proper shelving, and correct cleaning tools prevents depreciation and should be factored into the total cost of ownership.

- Context Creates Premium Value: Beyond the model itself, value is maximized by creating a historically accurate and complete scene. Period-correct Ground Support Equipment transforms a static model into a dynamic, high-value diorama.

How to Pair Correct Ground Support Equipment with Specific Aircraft Eras?

For the sophisticated investor, maximizing the value of a collection goes beyond simply acquiring and preserving individual models. The highest tier of collecting involves creating dioramas—detailed, historically accurate scenes that tell a story. In this context, Ground Support Equipment (GSE)—fuel trucks, baggage carts, starter units, and crew figures—are not mere accessories. They are critical value multipliers that transform a static model into a compelling investment piece.

A model aircraft displayed with incorrect GSE for its era is a historical anachronism that immediately signals a lack of expertise to discerning collectors. Conversely, a perfectly matched diorama demonstrates deep knowledge and elevates the entire display to a work of art. This attention to detail is directly rewarded in the market.

Case Study: The Diorama Premium

Professional diorama builders consistently find that period-correct ground support equipment can increase a display’s perceived and actual value by 25-40%. At a recent collector’s auction, a 1:72 scale diorama of a WWII B-17 Flying Fortress, complete with authentic 1940s-era fuel trucks, bomb carts, and correctly uniformed crew figures, sold for nearly triple the standalone value of the aircraft model itself. The premium was paid for the research, accuracy, and storytelling of the complete scene.

To achieve this level of accuracy, you must match your GSE to the specific time period of your aircraft. Using a modern pushback tractor with a 1960s-era Boeing 707 is a glaring error. The following guide provides a basic framework for era-matching:

- 1940s-50s Piston Era: Use propeller start carts (e.g., “Hucks” starter), vintage fuel bowsers, and simple, manual tow bars. Crew figures should be in period-appropriate attire like leather A-2 jackets.

- 1960s-70s Early Jet Age: This era requires air start units (ASUs) and ground power units (GPUs). Fuel trucks become larger, and the first containerized baggage carts appear. Airline crew uniforms are classic and distinct.

- 1980s-Present Modern Era: Modern pushback tractors, containerized cargo loaders (“K-loaders”), and advanced GPUs are standard. Crew figures should wear high-visibility safety gear.

The ultimate tool for ensuring accuracy is photographic evidence. Use online archives, aviation museum websites, and historical books to cross-reference the exact equipment used with your specific aircraft, airline, and time period. And crucially, always ensure the GSE is the exact same scale as the aircraft model; mixing scales immediately shatters the illusion of realism.

By applying these principles of material science, risk mitigation, and historical context, you transform your collection from a passive hobby into a managed portfolio of tangible assets, positioned for long-term stability and growth.

Frequently Asked Questions about Die-Cast Model Maintenance

Can I use regular glue to fix a loose stand?

Avoid permanent adhesives that could damage the model’s value. Use reversible solutions like clear nail polish or Teflon tape to thicken the stand’s peg for a tighter fit.

How do I prevent stand damage in the first place?

Always support both the model and stand together from the base when moving, never lift by the aircraft itself, and ensure stands are appropriate for the model’s weight.